Learning Flintknapping

Darrell Ross

Practicum in Anthropology, Dr. Terry Powis

Introduction

“If I would study any old, lost art, I must make myself an artisan of it.”

F. H. Cushing (1895)

I have very fond memories of looking for arrowheads and fossils as a boy. My friends and I would walk dry North Texas creek beds and look for these treasures. Fossil ammonites were almost as common as the river stones themselves, and petrified wood nearly so. The real treasure was finding an arrowhead. These were our prized possessions, and I still have an old cardboard box somewhere with a few of these in it. As I reflect on it some 40 years later, I’m fairly certain that the excitement and wonder that I felt as a boy contributed to my desire to study archaeology.

While pursuing my degree, I quickly focused on lithics. I find these artifacts particularly compelling because these are the things that last the longest. For example, the Oldowan tool industry is dated via potassium-argon methods back to 1.9 million years BP (Bordes 1968, 39-48). Lithics are often the only tangible remnants of a culture that survive to the present. They and the artifacts of their production in the form of debitage are certainly the most numerous artifacts of the past. For me, there is also something incredible about holding these artifacts in my hands. I constantly appreciate that I am literally touching something that another human made – in some cases – thousands of years ago. It is a tangible and personal connection to the past.

I had seen demonstrations of flintknapping done several times and admired the resulting tools (Figure 1). In a natural progression, I wanted to learn to work chert myself. It is my opinion that having a practical knowledge of how these tools are produced and the effort it takes to produce them informs our understanding of the original culture. If we understand how the tools may have been made, then we can begin to understand the resources required and the manufacturing process. Of course, we have very little in the way of a written record on how these lithic artifacts were produced. We, as experimental archaeologists, are reproducing the tools based on the evidence we find in the debitage and the finished artifact. Of course, we cannot be certain that the methods we use today are identical to those used by the original craftsperson, but we can gain insight into their culture by examining and approximating the manufacturing process.

I began trying to learn to work chert in 2019 after I attended a Kennesaw State University archaeological field school located at the Cummings site near Cartersville in Bartow County. I was encouraged by my professor, Dr. Terry Powis, to pursue the skill and explore its value as it pertains to archaeology. As a good 21st century scientist, I began my research with a simple Google search – “flintknapping videos”. I don’t recall how many results I returned on my first searches, but as of this writing you will receive approximately 73,200 results. I watched multiple of these and combined what I learned there with the knowledge I had gained during formal classroom instruction. I also read several articles and books, particularly by the deans of modern flintknapping, Francois Bordes and Don Crabtree. I also studied the case of Ishi, in particular his tools and their construction. When I felt I had a good understanding of the basics, I began to try to work pieces myself.

I quickly learned several hard lessons. First, do not wear shorts and flip-flops while trying to work a piece. Razor sharp pieces of debitage do not feel good in between your toes or in your knee. Second, no matter how hard I tried and how many videos I watched, I could not duplicate the nice flakes that I saw other people making. I would either produce short stubby flakes that ended in what knappers refer to as a hinge fracture, or I would shatter the piece completely. I spent a great deal of time over a period of months attempting simply to make a nice preform with no success.

I had reached a point where I felt I had exhausted the books and online resources, and I was not making any progress. During my archaeology field school, I was fortunate enough to meet a master knapper, Carl Etheridge, who was willing to donate his time to teach me flintknapping. Specifically, Carl would watch what I had learned online and tell me where I was making mistakes. With support from Dr. Powis, we agreed to meet weekly in Bartow County, once again at the Cummings site. We would have multiple training sessions at the Cummings site near Cartersville. During our first session together, Carl was able to point out several key mistakes that I was making. It was quickly made apparent to me that there are “tricks of the trade” that aren’t adequately relayed in online resources or books. I made more progress in that single session than I had in almost a year of my own study. Appendix A contains a pictorial sequence of the lithics I produced over the course of the research and demonstrates the rapid progression I made under direct instruction.

In this paper, I will discuss my applied research learning the lithic reduction sequence and manufacturing process. A brief overview of key figures in lithic experimental archaeology is provided for context. A comparison of the various learning methodologies follows, and the paper concludes with a critical analysis of my own progress as a novice knapper.

Research Methods

This research attempted to evaluate the efficacy of various learning modalities as they apply to teaching a novice the lithic manufacturing process. Sources evaluated included books, academic journal articles, web sites, and online multimedia resources such as YouTube videos. I had previously received formal training in archaeology including a field school and laboratory courses. I reflected on my prior training to filter sources to those relevant to the research.

H. Bernard Russell tells us “People will know it if you don’t” (2006, 96). With the research goal of actually learning the lithic reduction sequence and replicating it in mind, I began my research by searching specifically for books that dealt with the subject from a practical application approach. In this research, I was not particularly interested in typologies or classification methods, but rather the manufacturing process required to produce lithic tools and the resources required for that process. I also needed resources that approached the subject at a beginner level. I quickly settled on John C. Whittaker’s Flintknapping: Making and Understanding Stone Tools (1994) as a primary literary resource.

Whittaker is very readable for a beginner and explains important basic concepts including conchoidal fracture and Hertzian cone theory early on in the book (1994, 12-13). The book contains a brief history of flintknapping, as well as chapters dedicated to each of the major knapping techniques including both hard and soft percussion techniques as well as pressure flaking. Whittaker also provides important information on procuring raw materials and the necessary tools. Most importantly, the book emphasizes safety with a short, but detailed chapter on the obvious dangers of flintknapping like getting cut and the not-so-obvious such as silicosis (Whittaker 1994, 79-83).

I traced additional sources from Whittaker including Francois Bordes’ The Old Stone Age (1968) and Don E. Crabtree’s Introduction to Flintworking (1972). Both are considered classics in the field of flintknapping. The Old Stone Age is an exhaustive typology that covers the period from the Lower Paleolithic to the Upper Paleolithic and includes geographic maps of finds as well as excellent illustrations of lithic artifacts. Crabtree’s monograph is a much more practical explanation of the process of flintknapping and is mainly concerned with practical mechanics of working stone.

At this stage, I systematically moved on to scholarly journals and articles. I consulted articles on the history of flintknapping experimentation (Johnson et al. 1978), the life and times of Ishi (Torres 1984), and heat treatment of chert (Mandeville 1973, Mercies and Hiscock 2008). I familiarized myself with the geology of chert from an archaeologist’s perspective (Luedtke 1992), and with Georgia’s chert geology from a geologist’s point of view (Goad 1979).

I also viewed over 40 hours of YouTube videos of varying quality and usefulness. My goal here was to be able to observe the movements of knappers and variations in their technique. I quickly found that the quality of the material is directly related to the search terms used. If, for example, the search term “make an arrowhead” is used, a large number of results will be returned, but the majority are useless in an archaeological context. Experience quickly showed that searching for the terms “primitive technology” and “flintknapping” yielded the best results for my research. However, it was still necessary to be discriminating while watching the video.

Having a firm intellectual background and grasp of the basic skills and techniques required, I began my research in earnest by entering stage one of the manufacturing process – acquisition of raw materials (Collins 1974). I began by collecting glass bottles to use as raw material as recommended by Whittaker (1996, 67). In addition, I made my own flintknapping tools (Figure 2). I constructed a percussion tool, or billet, from a wooden dowel and a copper pipe end. I cut the dowel down and sanded it to make a serviceable handle. I melted lead fishing weights, outdoors of course, and poured the molten lead into the pipe end. I then attached that heavy weighted portion to the handle with epoxy. In an ill-advised attempt to replicate Ishi’s tools, I inverted the handle of the tool and attached a pressure flaker made from a copper nail to the end opposite the weighted billet (Torres 1984). Later experimentation showed that this was not an efficient tool configuration for the techniques that I eventually adopted. Finally, I constructed a leg pad from an old pair of denim jeans and a hand pad for pressure flaking from the same denim material. A couple of oven pads sewn in as a lining provided sufficient padding and protection for my flintknapping experiments.

With unbridled enthusiasm, I moved on to stage two of the lithic reduction sequence – core preparation and initial reduction (Collins 1974). I began experimenting with knapping in my back yard using the bottoms of glass bottles as raw material. In short order, I got very good at knocking the bottoms of those bottles out in whole or nearly whole pieces and cleaning up the rough edges with the billet. At that point, my accumulated knowledge failed me. I had an academic understanding of what was required, but I could not produce an adequate preform.

In May of 2021, I began to attend in-person instruction with Carl Etheridge in Bartow County at the Cummings site. Under Mr. Etheridge’s direction, I was quickly able to understand where I was making mistakes in my technique. I gained a deeper comprehension of selecting the proper material, having the correct tool configuration, and using different techniques to accomplish specific tasks such as removing a hinge fracture. I also learned the importance of “practice, practice, practice…” (Carl Etheridge, personal communication, June 12, 2021) (Figure 3). There is no substitute for simply picking up tools, grabbing raw material, and practicing. With Mr. Etheridge’s vast knowledge and patient assistance, I was eventually able to progress through primary trimming of the preform, considered stage three in the manufacturing process, and finally stage four or secondary trimming. In my case, a complex technique was used in stages three and four that involved both percussion and pressure flaking.

The final experiment was to reproduce one or more points previously excavated in Bartow County from the Cummings site. I was provided twenty points as a catalogue to choose from. The experiment required that I use the techniques and knowledge I had acquired to reproduce the point as closely as possible in terms of length, width, and thickness, as well as type. The raw material used would be as close to the original material as was readily available to me. I was not required to spall my own cobbles and was allowed to use previously created spalls as a starting point. The reproduction point I produced was then compared against the original for accuracy.

A Brief History of Flintknapping in Archaeology

Flintknapping has a long history in the field of archaeology. The study of worked lithic artifacts and their manufacture has been ongoing for over 150 years. The first published scientific work on the topic of flintknapping and its importance in the study of human history dates back to 1868. L. Lewis Johnson et al. (1978, 337) quote the following passage from Sven Nilsson’s The Primitive Inhabitants of Scandinavia:

“When, more than forty years ago, I first began to collect, I found here and there stones which had evidently been fashioned by the hand of man for some special purpose, and which showed distinct traces of strokes or knocks against some other equally hard, but more brittle stone. Having from my earliest youth made a practice of chipping flint-stones, and giving them any shape which I desired, I was able to recognize in these stone hammers the instruments by means of which the flint weapons had in ancient times been made.”

Although Nilsson did not attempt to duplicate the artifacts he found, the publication of his work is credited with beginning the scientific analysis of lithic tool manufacture via flintknapping (Johnson et al. 1978).

The recognition of the importance of flintknapping as it pertains to ancient cultures continued through the 20th and continues today. Interest in the study of flintknapping ebbs and wanes, but it never becomes obsolete. Below, I summarize the main figures in the history of the field with a focus on those that I attempted to emulate during the course of my research.

Ishi

Ishi was the last surviving member of the Yahi, a small tribe of indigenous people located in the Sacramento Valley (Figure 4). The discovery of gold at Sutter’s Mill and the settlement of the nearby valleys for agriculture resulted in a wave of slaughter that eventually eliminated the native cultures in the area. The Yahi managed to hold out longer than most of the local tribes. However, by 1908 we know that only four members of the Yahi tribe survived – an unknown man and woman, an old woman that was likely Ishi’s mother, and Ishi himself. A group of surveyors stumbled upon their encampment on November 10, 1908. The man and woman died while trying to escape across a creek, and the old woman died a few weeks later. Ishi lived alone in the wilderness until he was caught at a slaughterhouse near Oroville, California in August of 1911 (Torres 1984). Originally jailed, Ishi eventually came under the care of Dr. T.T. Waterman at the University of California Museum of Anthropology. Ishi demonstrated a number of Yahi traditional skills while at the museum, including his remarkable flintknapping ability. Ishi remained at the Museum demonstrating his skills until his death from tuberculosis in 1916 (Whittaker 1994).

Ishi was an expert pressure flaker and had mastered the expanded notch technique. Points made in his style are generally referred to today as Ishi points. During the period he lived alone, Ishi supplemented his native supplies by collecting other materials from the outskirts of settler’s camps. He used glass bottles for a blank just as readily as stone. Ishi likely used antler as his primary tool material early on during his evasion and survival, but when iron nails and rods became available, he quickly switched to iron tools because they required less sharpening. Today, a long pressure tool with a nail embedded in the distal end is called an Ishi stick amongst flintknappers. A surviving set of Ishi’s tools is curated at The Lowie Museum of Anthropology, University of California at Berkley (Torres 1984).

François Bordes

Born in 1919 in Southwestern France, François Bordes is an interesting and eccentric figure in European archaeology. He interests in geology and archeology began as a boy near his home in the Perigord. Bordes would tour the area on his bicycle and became intimately familiar with the geology and archaeology of the region. His enthusiasm and intellect allowed him to, at the age of fifteen-years old, be granted a permit to excavate a rock shelter at Le Roc de Givaudan. In 1936, Bordes enrolled at the University of Bordeaux majoring in geology and biology. At the outbreak of World War II, Bordes joined the French Resistance and eventually joined the French military until he received a serious wound from a grenade. After the war, Bordes pursued and received his doctorate in 1951 at the Sorbonne. In 1956, he returned to teach at the University of Bordeaux and would remain the titular overseer of Paleolithic archaeology in Southwest France until his death from heart failure in 1981 (Sackett 2014).

Within the field of archaeology, Bordes is primarily acknowledged for his revision of the approach to lithic typology. Traditionally, lithic specialists had approached typology rather rigidly. The focus of typology was on the systematics or quantifying the typological variation among assemblages. Little or no attention was paid to paleoethnological interpretation of these assemblages. Bordes reformulated this approach. His excavations focused primarily on increasing the quantity and quality of the data collected. All lithic materials including debitage were carefully collected and documented. Samples of related data in terms of stratigraphy, faunal, and palynological data were recorded along with the lithic artifact. The overall result was a more holistic view of the prehistoric archaeological record (Sackett 2014).

With regards to flintknapping specifically, Bordes is recognized as a pioneer in replicating Paleolithic tool assemblages. Bordes collaborated frequently with Don Crabtree during their careers. Their experiments and demonstrations in the 1960s and 1970s proved the value of experimental flintknapping as archaeological research (Whittaker 1994, 59).

Don Crabtree

Don Crabtree was born in Heyburn, Idaho in 1912. Crabtree began experimenting with flintknapping as a young man (Whittaker 1994, 59). Upon graduating high school, he moved to California and enrolled at Long Beach Junior College intending to study geology and paleontology. After one semester, he dropped out of school and continued his studies on his own. He remained self-conscious about his lack of formal education throughout his life and disliked public speaking. Crabtree worked at several California universities as a lab technician in both paleontology and archaeology. In 1939, he was diagnosed with cancer. He survived, and while recovering, he used flintknapping as an exercise to improve his coordination and muscular strength. In the spring of 1941, fully recovered, he demonstrated flintknapping at the American Association of Museums annual meeting. His performance resulted in several universities and museums requesting his talents as an advisor. With the outbreak of World War II, Crabtree returned to California and joined the war effort. After the war concluded, he became a country supervisor for the U.S. Department of Agriculture’s Agricultural Stabilization and Conservation Service from 1952 until 1962. He reentered the academic world in 1958 and remained at the University of Idaho until his death in 1980 (“Crabtree Lithic Technology Collection”).

Don Crabtree is widely considered the “dean of American flintknappers”. His skill and his collaborations with François Bordes are legendary amongst modern knappers. The majority of his written work is available only in articles in the journal Tebiwa, but it is possible to find copies of An Introduction to Flint Working which I personally consider a true treasure of information. The main thing that is impressive about his work is the level of detail. Crabtree exhaustively explores and describes artifacts to include the potential techniques used to manufacture them.

Carl Etheridge

As related to me in personal communication, Carl Etheridge began flintknapping in the 1970s through an interest in collecting points (Figure 5). As Etheridge relates in his own words:

“I guess you say the impetus behind all this was – after collecting points for quite a few years – picking up a point and looking at it. I thought to myself that it wasn’t that finely made. It was one of your rougher points, but it was an original. Just holding it my hand, I looked at it and thought – that guy, hundreds or maybe a thousand years ago, made that. He was not educated, but he knew how to work this rock. Why can’t I learn how to do it?”

During the 1970s, there were very few books on flintknapping available. Etheridge started flintknapping by experimenting on his own. He eventually became skilled enough to be able to do demonstrations at the Etowah Indian Mounds. During a demonstration, while knapping a point, two men came up and watched him for a while. One of the men asked, “That’s not bad, but would you like to do it better?” That man was Ron Cloud. Cloud was a close friend of Don Crabtree and had learned flint working directly from Crabtree. At this point, Etheridge began to study under Cloud and learned how to heat treat stone, notch, and other advanced flint working techniques.

Over the ensuing years, Etheridge has continued to refine his technique and acquire new ones. He currently does demonstrations for the Department of Geography and Anthropology at Kennesaw State University and participates in regional “knap-ins”. Etheridge also sells reproductions of points, knives, lances, arrows, and other primitive technologies for the enjoyment of his customers (Carl Etheridge, personal communication, July 2, 2021).

Carl Etheridge is a master knapper. He has encyclopedic knowledge of various flint working techniques including both direct and indirect percussion, pressure flaking, notching, and hafting. He is also intimately familiar with lithic typology and can often type a point from memory. In addition, he has a firm grasp of the chert geology of North Georgia and Bartow County and can readily identify local areas with good sources of raw material.

Results

The results of this research are presented below in two sections. The first section is a subjective evaluation of learning methodologies available to beginning knappers based on my own experience. The second section is a critical review of my own progress as a knapper. This appraisal took the form of a practical experiment to reproduce a projectile point excavated from the Cummings site in Bartow County. The Cummings site is a prehistoric Native American village that dates from the Middle Woodlands period to the Mississippian period (100 AD -1400 AD).

Evaluation of Learning Methodologies

I utilized three main resources to begin learning to work stone. The first method that I pursued was basic research in the form of books, both in print and online. I read multiple books by various authors with the intent of gaining a broad understanding of the manufacturing process and basic flintknapping techniques (Figure 6). Books and print media in general are an excellent way to gain a foothold and familiarization with the subject matter. In particular, books as a learning tool teach the beginner the proper jargon to communicate effectively within this highly specialized skill. It is vital for a novice to differentiate between a preform and blade, or understand the difference between a cobble and a spall. Books will also teach a beginner specialized vocabulary specific to flintknapping that are not in use in common language, with such terms as bulb of percussion and eraillure scar.

Second to vocabulary, the most important information that is effectively presented in print material is guidance regarding safety. When working with stone, there are important safety precautions that should be taken. It should be obvious that working with and around very sharp pieces of flaked stone requires caution. Hand and eye protection should be self-evident, but there are other hazards that aren’t so readily apparent. The dust produced during flint working can lead to a medical condition called silicosis. Silicosis is caused by inhaling dust generated during knapping. As such, a flintknapper should always work either outdoors or in a well-ventilated area (Whittaker 1994, 83).

Notwithstanding their value as a learning tool, books fall short in teaching actual technique. It is very difficult to effectively explain, in print, how to properly strike a platform or to describe a correct method of pressure flaking. Even books with extensive illustrations such as Crabtree’s Introduction to Flintworking fail to adequately demonstrate technique. Carl Etheridge has validated my own assessment and explained to me during a conversation that he had a similar experience with books. He had originally purchased a book when he first began flint working, but felt that it was not useful because the concepts were laid out in a fashion that made it difficult to comprehend (Carl Etheridge, personal communication, July 16, 2021).

After reading several books on the topic, I moved on to reviewing some of the available multimedia resources online. Specifically, I dove into YouTube. There are literally thousands of videos freely available on YouTube that show demonstrations of flintknapping. Most often, these videos are demonstrations of “how to make an arrow head” or something similar. It is important to be discriminating as to which videos are used as resources. It is equally important to view the video with a critical eye and evaluate the techniques demonstrated analytically or even skeptically. It is also imperative to have a grounded knowledge in basic technique and vocabulary prior to using online videos as a resource. Having that know-how allows the viewer to understand the presenter’s language and properly comprehend the context of the video.

The beauty of modern technology is that it is ubiquitous. YouTube videos are easily accessible on multiple devices including smart phones, personal computers, and smart televisions. This makes this particular learning resource portable and easily referenced even while working a piece. The other advantage is the sheer number of techniques demonstrated. Examples of working with modern materials as compared to original materials, referred to as “aboriginal knapping” in the flintknapping community, are common. In addition, lessons on both direct and indirect percussion, pressure flaking, and notching are all presented on various YouTube channels.

Similar to books, videos fall short in relating actual technique in a manner such that a beginner can translate the demonstrated procedure and replicate it. The main fault is that presenters on YouTube commonly leave out vital steps in the lithic reduction sequence in the interest of making a video that is of the appropriate length for the average viewer. This may lead a novice knapper to become frustrated when failing to replicate the resulting piece. There are very few videos that actually cover all the steps in the lithic reduction sequence from start to finish, and these are generally the same running time as a feature film.

As a caution, many videos that purport to teach knapping contain incorrect techniques. Once a beginner gains a certain level of skill, it is a fun and interesting exercise to revisit videos previously viewed. Mistakes and incorrect technique become glaringly obvious. In some cases, the presenter is even demonstrating a technique that is potentially dangerous. I have personally seen a video by a self-proclaimed survivalist in which the individual claimed to teach a person how to make a point from a glass bottle. I was shocked to see the presenter hold the glass bottle bottom up and even with his eye to pressure flake it. There is already a risk of a flake getting in a knapper’s eye, but to hold the raw material even closer to your face and then proceed to pressure flake without eye protection is foolhardy.

The final learning method that I had available to me was personal instruction from a master knapper. This is a traditional learning mode that has been used since antiquity to pass the craft of flintknapping from one craftsman to the next. There is a reason this learning methodology was and is favored by knappers. It is by far the most effective way to learn the skill.

The benefits of having a hands-on instructor fall into two categories. Unlike books and videos, there is no opportunity for gaps in the lithic reduction sequence. Working with an instructor, the pupil will necessarily be required to perform each step in the manufacturing process and become familiar with the technique required to perform each. The hidden “tricks of the trade” such as frequent abrading, planning piece layout, and the importance of choosing the correct raw material all go along with the basic instruction.

The other important benefit of being taught to work stone in a master-apprentice fashion is that the instructor provides an instant feedback loop to the student. The instructor can and should be providing constant direction to the student to correct both gross and fine mistakes in technique (Figure 7). Flint working leaves little room for mistakes when attempting to produce a final piece. It is not possible to put a flake back onto a core once it has been struck. The guidance of an in-person teacher can prevent miscalculations and errors on the part of the student. As a result, the beginner gains skill and experience at an exponential rate which in turn produces confidence.

In summary, all of the learning methods evaluated during the course of this research proved valuable in one manner or another. Books and other print materials are excellent primarily for grounding a novice in the vocabulary,

the academics of flint working technique, and, most importantly, safety. Online multimedia resources are ubiquitous and freely available. These video resources are also beneficial in that they demonstrate a wide variety of both tools and skills. As revealed during the course of the research, the most efficient learning modality is in-person instruction led by an experienced knapper. This learning method is unique in that the unseen skills either obfuscated or ignored by the other learning resources are expressly taught during the lithic reduction sequence out of simple necessity. In addition, the instructor provides an instantaneous assessment and correction of the student’s technique. Neither books nor videos are a substitute for the traditional modality of the master-apprentice relationship.

Practical Evaluation

The final experiment for the research took place on July 16, 2021 in Bartow County. During a flint working session, I attempted to reproduce a point that had been previously excavated at the Cummings site near Cartersville, Georgia. As previously mentioned, the Cummings site is a Native American village that date to the Middle Woodland and Mississippian periods (100 AD – 1400 AD). I attempted the reproduction entirely on my own from a raw chert spall without any assistance. The objective of the experiment was to practically evaluate my own personal skill in flint working following eight weeks of in-person instruction by Carl Etheridge.

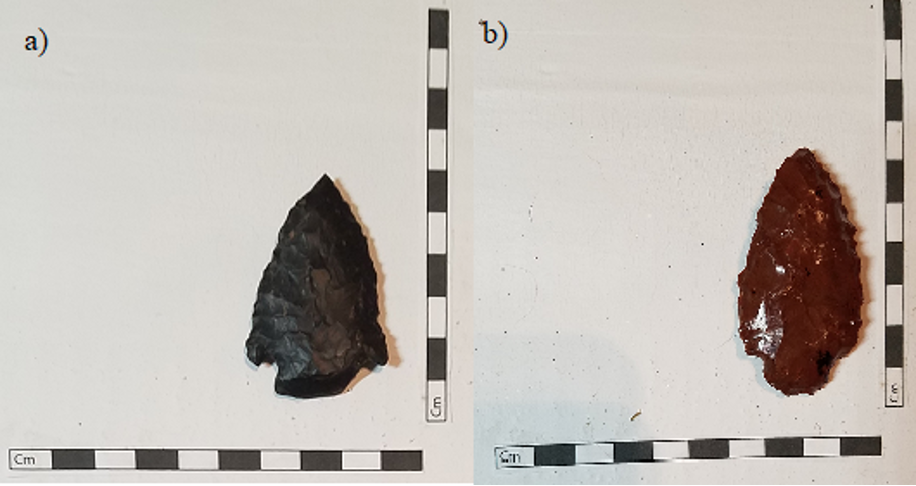

The point that I chose to reproduce was a leaf-style corner-notched projectile point. Prior to the experiment, I did a typology analysis on the point and identified it as a Jack’s Reef Corner-notched point (Jack’s Reef Corner-notched n.d.). Appendix B details the typology of the target point. The typology’s dimensions, style, and Middle Woodland cultural period are consistent with this artifact, and its location at the Cummings site in Bartow County.

I chose this point to replicate for several reasons. The point itself is of the best workmanship of all of the Cummings site points from which I was given as potential targets to reproduce. I had previously reproduced some of the less refined points provided, but the quality of this point demonstrated that it had been made by a craftsman of more than beginner skill. Gross visual analysis of the point shows that it had been made using a complex technique combining both percussion and pressure flaking (Crabtree 1972).

Other features that I was excited to attempt were the actual shape of the point and its style of notching. The point is leaf-like in shape and exhibits corner notches. My working sessions during training had focused on making Ishi-style points that are more acutely triangular shaped. I had done side notches and stemmed points prior to the experiment, but I had not previously attempted corner notches in any of my instructor-led or solo sessions.

In short, I chose a point that would tax my current level of skill to the limit. The point was of an unfamiliar shape and new style. It had also been created using a corner notching method that I had never attempted.

The result of the experiment was that I failed to accurately reproduce the point I had selected on the first attempt (Figure 8). I was accurate in reproducing the distinctive shape of the point. I was also relatively accurate in producing a point of the same length and width dimensions. Table 1 below illustrates the dimensions of the reproduction as compared to the dimensions of the original artifact. All measurements are taken with sliding calipers and recorded in millimeters.

Table 1. Comparison of dimensions

| Dimension | Reproduction | Original | % Difference vs Original | |

| Length | 52 | 46 | 13% | |

| Width | 26 | 28 | -7% | |

| Thickness | 6 | 4 | 50% | |

The additional length of the reproduction is attributable to my plan to conserve some material in anticipation of length loss during the notching process. The slight reduction in width is due to the realization during pressure flaking that the point was too thick. I lost width in the preform while attempting to thin the point further using pressure.

The key error during manufacture was that I did not succeed in thinning the preform enough during the initial percussion of the raw spall in stage three of the manufacturing process. Once pressure flaking is begun, additional thinning becomes much harder because of the difficulty associated with creating a conchoidal fracture through the preform mass with pressure techniques. It is not possible to generate enough force via pressure to remove the required stone to further thin the piece without consuming additional material. At this stage, I could only thin the reproduction further through pressure flaking which would continue to reduce the overall length and width of the finished piece. While only two millimeters, the added thickness has follow-on consequences to the overall appearance of the finished reproduction. It should be immediately noticeable that the required corner notches are not observable on the reproduction. The additional thickness makes corner notching extremely difficult if not impossible. This additional thickness and its consequent impacts on the reproduction are the primary reasons I deem this reproduction a failure.

The additional thickness in the piece is a common mistake made by novice knappers (Carl Etheridge, personal communication, July 16, 2021). Nevertheless, I have gained enough knowledge and skill in flintknapping to recognize the problem and its follow-on effects in the overall piece. I also know what to correct and how to correct it. As a result, I do not consider the experiment itself a failure, but rather a reflection of the knowledge I have accumulated during my research. I will, of course, continue to attempt to reproduce the point until I have a viable replica of the original artifact.

Conclusion

From my perspective, future research in the field of lithic analysis in Georgia falls broadly into two categories. First, the geology of chert in Georgia is sparsely documented. There is a paucity of reference material available to geologists and even less from the perspective of an archaeologist. There is an immediate need for a collaborative study between archaeologists and geologists that documents the available chert resources in Georgia, catalogues the identifying characteristics of the raw material, and maps sites as prehistoric sources of raw material for lithic tool manufacture. Archaeologists and laypersons with experience in flintknapping are crucial to this study. They are uniquely qualified to evaluate the quality and workability of the raw material in terms of its value in the lithic manufacturing process and therefore its desirability.

Second, using the results of the study mentioned above, lithics recovered at various sites could potentially be traced to the origin sources of raw material. This would help establish trade and procurement patterns. As applied to the Cummings site, this information would aid in identifying the relationship between Cummings and other nearby contemporary archaeological sites.

In this research, I have explored flintknapping and how novice archaeologists can pursue this ancient and honorable craft. Flintknapping has a long and well-deserved history in academia. Practical application of the techniques required to properly manufacture stone tools informs our understanding of the manufacturing process. This is a relevant and applicable tool for archaeologists. In the process of learning to work stone, archaeologists also learn to recognize and analyze the distinctive tool marks left during the lithic reduction sequence – i.e. how the artifact was made. Being able to identify these tool marks as well as accurately evaluate the level of skill required to produce an artifact based on personal experience in turn advises our overall understanding of the culture that made the artifact originally and helps to answer why the artifact was made.

Acknowledgements

I would like to thank Ann Cummings, for whom the Cummings site is named, for allowing both myself and other students to excavate sites on her private property as well as study the artifacts that are recovered there. I don’t believe the number of students that have been positively affected by the field schools held at the Cummings site can be overestimated.

I would also like to thank Dr. Terry Powis who has acted graciously as my research sponsor and mentor. I am in his debt for sharing his knowledge, time, and research materials. Without his guidance and direction, this research would not have been possible.

I want to acknowledge my other professors within the Department of Geography and Anthropology at Kennesaw State University as well. Each course I’ve taken has been both educational and entertaining. I applaud your efforts at introducing students to this fascinating field of study.

I suppose I must also thank my family and my parents. They have been subjected to hours of documentaries with only the occasional sigh and rolling of eyes. They have had to suffer with chert flakes in their clothes and shoes. They have been my forced audience while I opined on the difference between a “good” knapping rock and a “bad” knapping rock. In particular, I need to thank my son, Devin, whom I have hauled to excavations, knapping sessions, and museums – often with no more reward than a chicken biscuit.

Finally, I must thank Mr. Carl Etheridge. Carl selflessly volunteered his time and energy to teach me flintknapping. He has been a sometimes tolerant and sometimes cantankerous mentor who has generously shared his knowledge, tools, materials, and time with a very slow learner. I hope I can do him justice some day and pass this craft on to a new generation.

References

Bernard, H Russell. 2017. Research Methods in Anthropology: Qualitative and Quantitative Approaches. Lenham: Rowman & Littlefield.

Bordes, Francois. 1968. The Old Stone Age. World University Library. McGraw-Hill, New York.

Collins, Michael Bruce. 1974. “A Functional Analysis of Lithic Technology among Prehistoric Hunter-Gatherers of Southwestern France and Western Texas.” PhD diss. University of Arizona, 1974.

Crabtree, Don E. 1966. “A Stoneworker’s Approach to Analyzing and Replicating the Lindenmeier Folsom,” Ariel 129, vol. 129, pp. 92-114.

Crabtree, Don E. 1972. “An Introduction to Flintworking,” Occasional Papers of the Museum, Idaho State University 28, vol. 28, pp. 1–98.

“Crabtree Lithic Technology Collection.” n.d. https://www.uidaho.edu/class/anthrolab/collections/crabtree.

Cushing, Frank Hamilton. 1895. “The Arrow,” American Anthropologist 8, vol. 8, no. 4, pp. 307–49.

Glock, Waldo S. 1920. “The Use of the Terms Flint and Chert.” Proceedings of the Iowa Academy of Science, vol. 27, no. 1, pp. 167-173.

Goad, Sharon I. 1979. Chert Resources in Georgia: Archaeological and Geological Perspectives. University of Georgia.

“Jack’s Reef Corner-notch Projectile Point.” n.d. www.Projectilepoints.Net. University of West Florida. Accessed July 5, 2021. http://www.projectilepoints.net/Points/Jacks_Reef.html.

Johnson, L. L., Jeffery A. Behm, François Bordes, Daniel Cahen, Don E. Crabtree, Dena F. Dincauze, Conran A. Hay, et al. 1978. “A History of Flint-Knapping Experimentation, 1838-1976 [and Comments and Reply],” Current Anthropology 19, vol. 19, no. 2, pp. 337–72. http://www.jstor.org/stable/2741997.

Luedtke, Barbara E. 1992. An Archaeologist’s Guide to Chert and Flint. University of California, Los Angeles.

Mandeville, Margaret D. 1973. “A Consideration of the Thermal Pretreatment of Chert,” The Plains Anthropologist, pp. 177–202.

Mercieca, Alison, and Peter Hiscock. 2008. “Experimental Insights into Alternative Strategies of Lithic Heat Treatment,” Journal of Archaeological Science 35, vol. 35, no. 9, pp. 2634–39. https://doi.org/https://doi.org/10.1016/j.jas.2008.04.021.

Sackett, J. 2014. “François Bordes and the Old Stone Age,” Bulletin of the History of Archaeology 24, 24 (January): Art. 3. https://www.archaeologybulletin.org/articles/10.5334/bha.243/.

Torres, Dennis. 1984. “Ishi,” Central States Archaeological Journal 31, vol. 31, no. 4, pp. 175–79. http://www.jstor.org/stable/43137417.

Whittaker, John C. 1994. Flintknapping: Making and Understanding Stone Tools. University of Texas Press.

Appendix A – Pictorial Sequence

Appendix A is a pictorial sequence of the points made during the research period from May 21, 2021 to July 9, 2021.

Appendix B – Target Point Typology

Point Typology Analysis

Location

Site: Cummings

Date of Find: 23 Oct 2020

Excavated By: J. McFarlane

H. Redman

Unit: 4

Level: 1

Depth: 18cm

Measurements

Length: 46mm

Width: 28mm

Thickness: 4mm

Stem Length: 8mm

Stem Width: 20mm

Type

Type: Jack’s Reef Corner-notched

Period: Woodland

Date: 1,500 – 1,000 B.P.